A DC motor converts direct current electrical energy into mechanical energy by using direct current. Various types of this rotary electrical device exist, all with either electronically or electromechanically controlled internal mechanisms that change the direction of current in the motor. This guide covers dc motor, dc motor parts, and other information in detail.

Working on dc motor

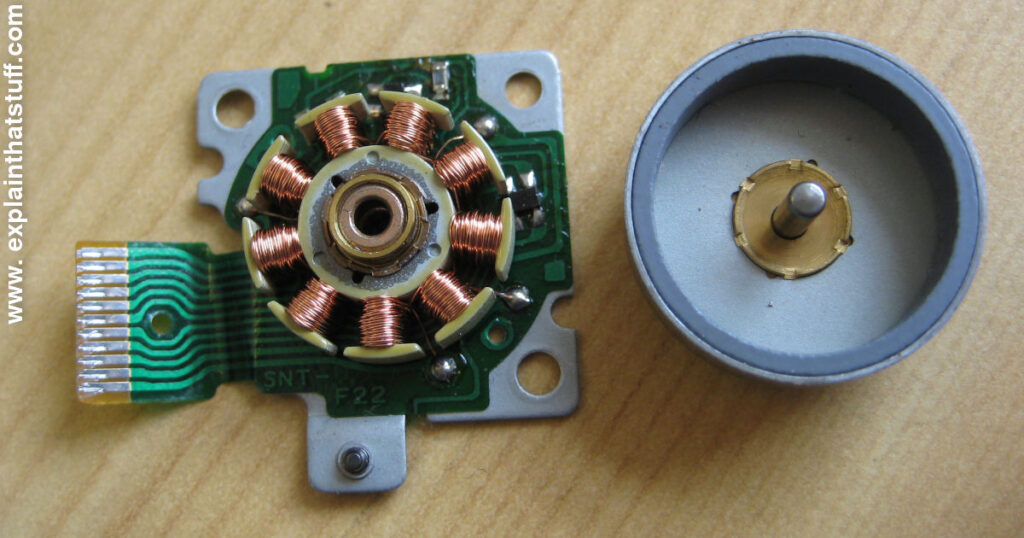

A DC motor is a fascinating machinery commonly used in various industries and applications. Working on a D.C. motor requires a basic understanding of its components, including the stator, rotor, commutator, and brushes. One of the first steps in working on a D.C. motor is to identify the type and model of the motor to ensure that you have the correct tools and knowledge to handle it.

To begin, inspecting the motor’s external components, such as the frame, terminal box, and end bells is essential to ensure that they are in good condition. Once the motor is disassembled, you can inspect the internal components, including the armature and the commutator. Checking the armature’s windings for damage or shorts is crucial, as imperfections can significantly impact the motor’s performance. Additionally, you should clean the commutator with a suitable cleaning solution and inspect the brushes to ensure they are not worn out.

When working on a D.C. motor, it is also important to pay close attention to the bearings, as they play a critical role in maintaining the motor’s efficiency and reducing friction.

Let’s take a closer look at a part of a multipolar DC motor. In an armature, when field magnets stimulate armature conductors, the conductors experience a force that causes the armature to rotate. Under N-poles, the conductors are assumed to carry the current downward, while under S-poles, the current is assumed to carry upward. Fleming’s Left-hand rule must be applied to find the force’s direction on each conductor.

An anti-clockwise rotation of the armature is caused by force ‘F’ experienced by each conductor. Commutators reverse the current in each conductor during the transition between poles in order to produce continuous and unidirectional torque.

DC motor parts

Read more: What Are MCC panels? Each And Everything You Need To Know About MCC panels

The Rotor

DC motors have a rotating electrical component called a rotor. It is a part that rotates electrically. DC motors have rotating parts called rotors. A voltage is applied to the armature winding, causing it to move dynamically. DC motors can be driven in this way to produce mechanical movement.

The Stator

A stator is a stationary electrical part of a DC motor. It comes from the word “stationary.” Stators are non-moving parts that provide a magnetic field around rotors when applied voltage.

Brushes of DC motor

As the last part of the DC motor parts list, carbon or graphite brushes are available. Brushes with the commutator serve as bridges by connecting the rotor to the static electrical circuit. An external circuit communicates current from the commutator to brushes located near the commutator. Therefore, the current flows through the armature’s windings.

The Yoke

A DC motor part called a Yoke is another unit of the motor. Yokes are protective magnetic frames made from cast iron or steel, often made of cast iron. As well as protecting the motor’s inner parts, this protective cover also supports the motor’s armature. Besides housing the magnetic poles and field windings, the Yoke also holds the field system of a DC motor.

The Commutator

In the form of a split ring, a commutator is used. Based on the number of armature windings, the copper ring may be split into two or more. Armature windings are connected to the split segment.

Commutators deliver electric current to armature windings to provide power. As a result of their interaction with the North and South poles, armature and field windings produce a dc motor’s main working principle. It is thought that the North Pole generated by the armature will be attracted by the South pole created by the field winding, resulting in the rotor rotating. In this movement, a constant torque is produced in one direction by the rotor.

Commutators provide current switching for armature windings when attached to armatures. With insulator material like mica, each segment of the split ring is insulated from the other segment. As power passes from the supply to the brushes, the commutator, and the armature windings, it is distributed throughout the electrical system.

The Armature Windings

The armature winding is another DC motor component. Generally, DC motor armatures wind two types of armatures: lapped and wave armatures. There are differences in the number of parallel paths between them. During rotation, the armature winding alters the magnetic field created by the rotor’s rotation. In this process, magnetic losses are produced.

Using some low-hysteresis laminations of silicon steel in the armature core can reduce magnetic losses. A cylindrical armature core is formed by piling up the laminated steel sheets. Slots have been designed with the same material inside the armature core.

The poles

To ensure the rotor is rotating, the stator uses a specific sequence of magnetic poles to energize the poles. The poles are divided into two types: the pole shoes and the pole cores.

When magnetic fields are applied, the rotor begins to rotate in a DC motor. Magnetic fields are generated by windings around the Pole Shoe, which attaches to the Pole Core in the Yoke. These Pole Shoe and Pole Core parts are connected by applying hydraulic pressure. A yoke is holding the Pole Core, which is carrying the Pole Shoes with field windings attached to them. Between the rotor and stator of this pole unit, flux is generated and spread out into the air gap.

What are the applications of DC Motors?

DC motors are classified according to 4 different types used in various applications. There were several different types, and parts of DCs discussed in the previous sections. In this section, we discuss how DC motors can be used in a wide variety of circumstances and for a wide variety of purposes.

Since each type of DC motor has some specific advantages, they can be used in various ways. Small ones can be found in tools, toys, and a wide range of household appliances at home. Furthermore, DCs are used in braking and reversing applications in industries, as well as conveyors and turntables. As DC applications, we tried to give some specific examples:

Cars powered by electricity

The use of DCs in electric cars is another application. One of the most popular choices for electric vehicles is DC motors due to their energy efficiency and durability. Additionally, DCs have excellent starting torque and variable speeds with voltage input, which makes them popular among hobbyists.

Children’s toys

Small DC motors are the best choice of manufacturers and hobbyists for children’s toys such as remote-control cars and trains due to their ease of use and relative ruggedness. Various toys require different motors with varying voltages to meet the different speed and movement requirements. These specifications are all found in DCs, which manufacturers use.

The pump

A hydraulic pump is vital for almost every industry, including agriculture, construction, mining, manufacturing, and steel making. Powered by DC motors, these pumps provide excellent performance and are capable of being controlled at various speeds.

These easily maintainable motors have also helped DC motor pumps benefit from the development of lower-cost brushless DC motors that were used in ceiling fans.

The robots

Robots are electromechanical devices designed to accomplish a specific task. For hobbyists and engineers, robots are anything electromechanical. A DC motor is used for actuating something on a robot, like tracks, arms, or cameras, and it is trendy for several reasons.

Especially suitable for robotics, DC motors have high torque and efficiency, making them ideal for various applications.

How do DC motors differ from AC motors?

- In cases where precision control is required, DC motors provide a wide range of options. DC motors are therefore used in industrial machinery that requires high precision.

- A DC motor provides excellent torque, speed, and response characteristics when it starts, stops, or reverses directions.

- Battery electricity can be stored in electric vehicles in the form of DC. Due to this, DC motors can be used in electric cars.

Apart from this, if you are interested to know more about MCC panels then visit our TECH category.

FAQs (Frequently Asked Questions)

How do DC Motors work? What are their three essential components?

In the stator, brushes and magnets are contained, as well as the housing for the entire machine. Rotor winds are contained within the rotor, as are the communicator and the output shaft. The voltage must be applied to the two parts for the motor to move. Using DC motors in two directions is possible.

DC motor starters are made up of what parts?

There are three terminals on the 3-point starter that interface with the motor: the armature terminal, which links the motor armature winding with the positive supply pole; the line terminal, which connects to the field winding with the positive supply pole; and the field terminal, which connects to the field winding.